High-Accuracy Tools for Modern Machining

Built for accuracy, durability, and performance

High Accuracy Tools for Precise Machining

Reliable Performance in Every Cutting Job

Tools Designed for Industrial Applications

FEATURED PRODUCTS

Specialized in making all types of cutting tools as per customer requirement ranging from various outer diameter, thickness and bore in HSS grade materials

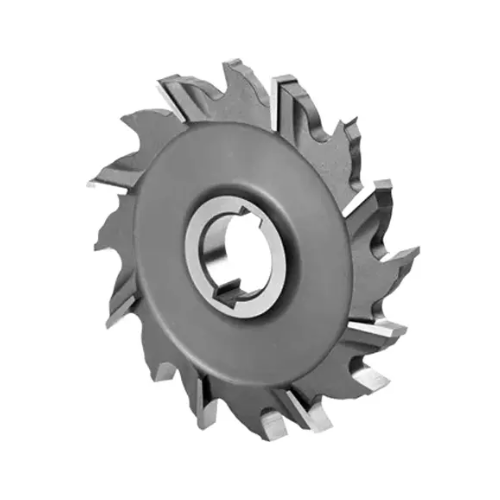

HSS Slitting Cutters (with or without keyway)

HSS Slitting Saws

- Manufactured by ESKENT using premium HSS and M35 grades

- Available outer diameter range from 10 mm to 315 mm

- Conforms to ISO 2296:2018, IS and DIN standards

- High tooth density with options up to 200 teeth on 20 mm diameter

- Achieves precision tolerance up to 5 microns on one side

- Supplied in uncoated, ground-finish condition

- Available in staggered tooth and fine tooth configurations

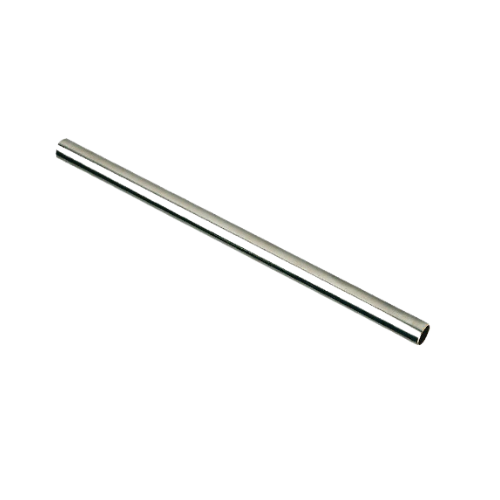

HSS GAP SIZING CUTTER

HSS Angle Cutters

- Material: M2, M35, M42

- Diameter: 32mm onwards

- Width: 8 to 36mm

- Bore : 10 to 27

- Cutting Direction: Right hand and left hand

- Usage /Application: Angular slots or chamfers

HSS Side and Face Cutters

Special HSS Tool Bits

HSS Reamers

Grow Your Business with Our High-Performance Cutting Tools

Understanding Requirement

We understand, customize, and deliver with precision. From first conversation to final result, we’re here to meet your needs with personalized support.

Design & Engineering

Our experienced team designs tools using the standard diagrams available and their experience since 30 yrs to ensure accuracy in product design and manufacturing

Timely Delivery

We ensure prompt and safe delivery, maintaining our commitment to reliability and customer satisfaction.

Quality Inspection

We rigorously test and inspect every tool to guarantee top-tier quality, industry compliance, and customer satisfaction

About Us

Eskent is a precision cutting tools manufacturer specializing in HSS and M35 tooling for industrial machining applications. We design and manufacture slitting saws, angle cutters, gap sizing cutters, splitting cutters, reamers, and special tools with a strong focus on accuracy, consistency, and dependable performance. Our tools are built to support real machining conditions across workshops, tool rooms, and manufacturing environments.

Works & Head office

ESKENT

C-30, KSSIDC Industrial Estate,

KIADB Industrial Area, Pillagumpa, Chokkohalli,

Hoskote, Bangalore – 562114, India.

One Stop Solution for Precision Cutting Tools

Call Us Now

Drop us an Email

HOW WE WORK

Our process is focused on understanding machining needs, manufacturing with precision, and delivering dependable cutting tools.

Requirement Analysis

We understand your machining application, material, dimensions, and performance expectations before recommending tools.

Precision Manufacturing

Tools are manufactured using HSS and M35 grades with controlled processes to ensure accuracy and consistency.

Quality Check & Dispatch

Each tool is checked for dimensional accuracy and finish before safe packing and dispatch.

Talk to Experts Before You Cut

Choosing the right tool matters. Get expert guidance on cutting tools designed for reliable industrial machining.

Trusted by Machining Professionals

What our customers say about our cutting tools, service support, and machining performance.

Eskent tools deliver consistent accuracy in our machining work. Reliable performance and good support make them a dependable supplier.

We use Eskent cutting tools regularly for milling and slotting. Tool life and finish quality have been consistently good.

The tools perform well under continuous machining. Quality and dimensional accuracy meet our workshop requirements.

Inquire About Products, MOQ, Pricing & Delivery Time

Contact our team to discuss product specifications, application requirements, and receive clear details on pricing and delivery.